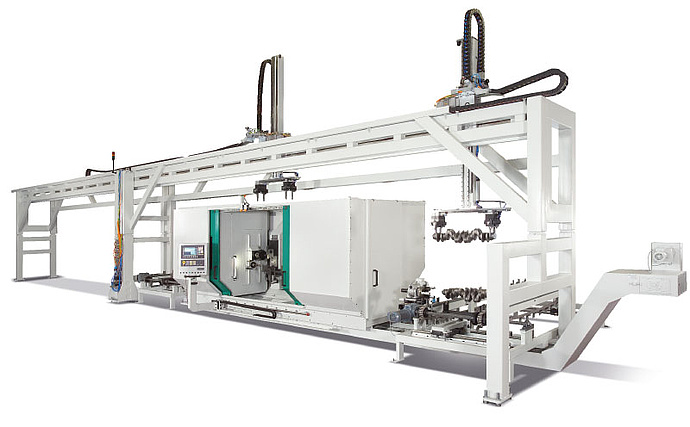

Enduro V 800

End processing system as vertical bed solution for machining of workpieces

from 20 to 400 mm diameter

Our fully automatic Enduro V 800 end processing system makes the processing of large series or heavy, long workpieces easier for you.

A significant time and cost-saving factor for your production: Processing operations, such as milling, drilling, centring and thread cutting, are carried out on both sides, in one work cycle and without manual intervention.

For processing:

- Hydraulic cylinder tubes

- Transmission shafts

- Camshafts

- Toothed racks

- Crankshafts

- and much more ...

Your benefits:

- Optional choice between manual and automated loading (robots, portal, timed conveyors, connections to upstream/downstream conveyor, buffer sections)

- The guide and linear rails are always kept free of chips

- Different processing operations are carried out on both sides, in one work cycle without manual intervention

As standard: up to 3 work spindles per side, special requests are possible - Automatic tool changer with double gripper

- Additional magazines up to 80 tools

- Individually adaptable and expandable due to modular design

EVERYTHING FROM A SINGLE SOURCE

Thanks to our integration into the Pütz Group and the resulting synergy effects we are able to offer you not only end processing machines and centres but also the appropriate testing technology to test surfaces and dimensional accuracy and completeness.